WIMTRONIC: Sensor Build

We designed the digital WIM sensor WIMTRONIC with respect to principles of road preservation. Also, we paid attention to weighing accuracy and the sensor's service life.

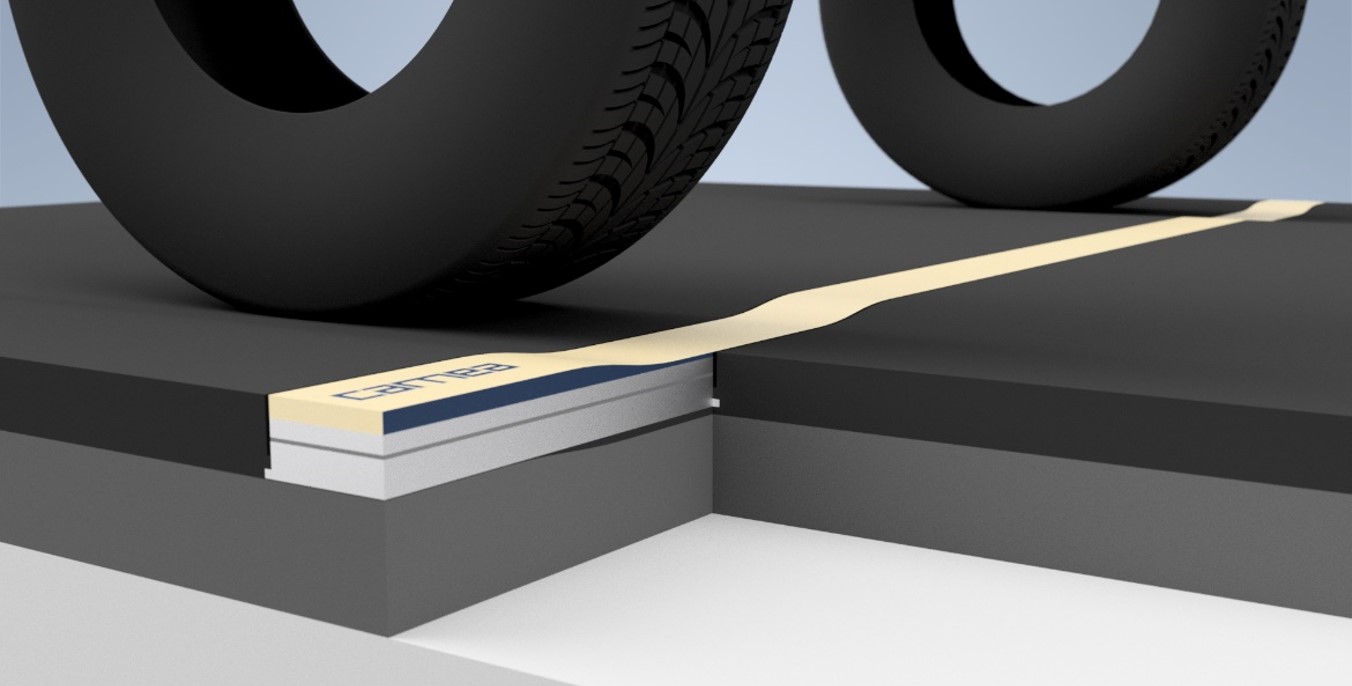

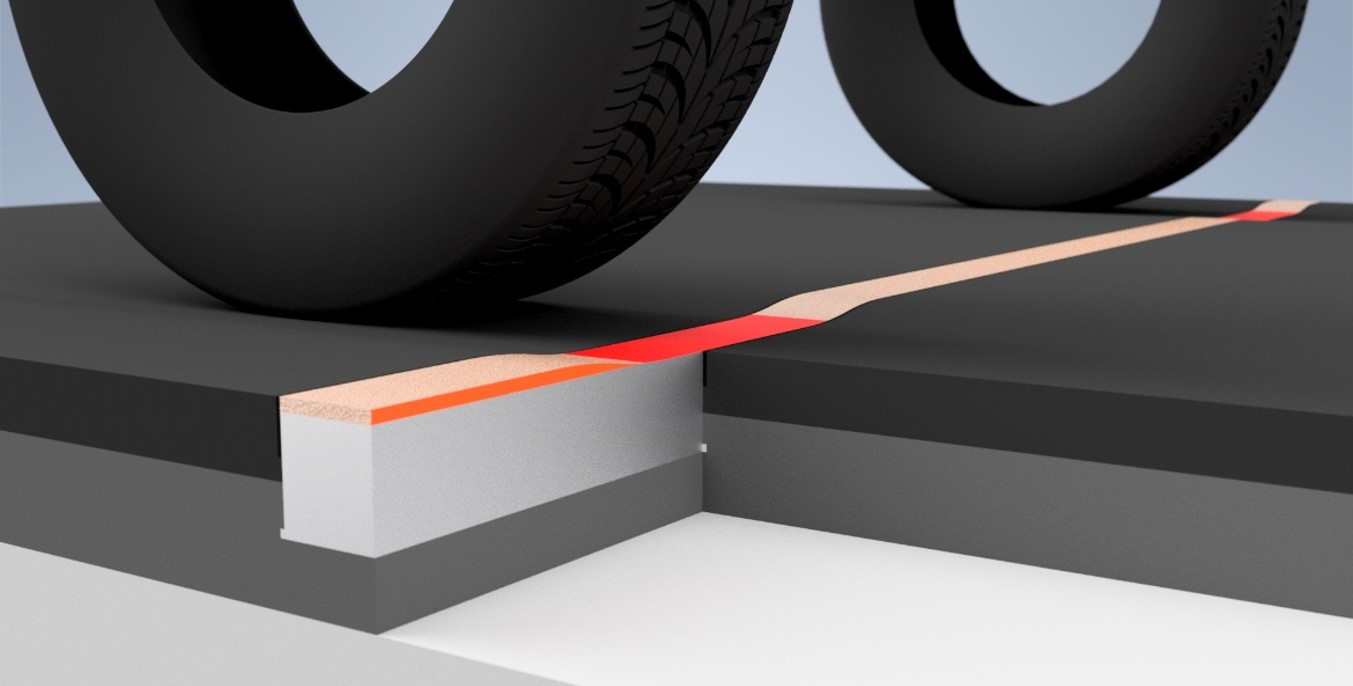

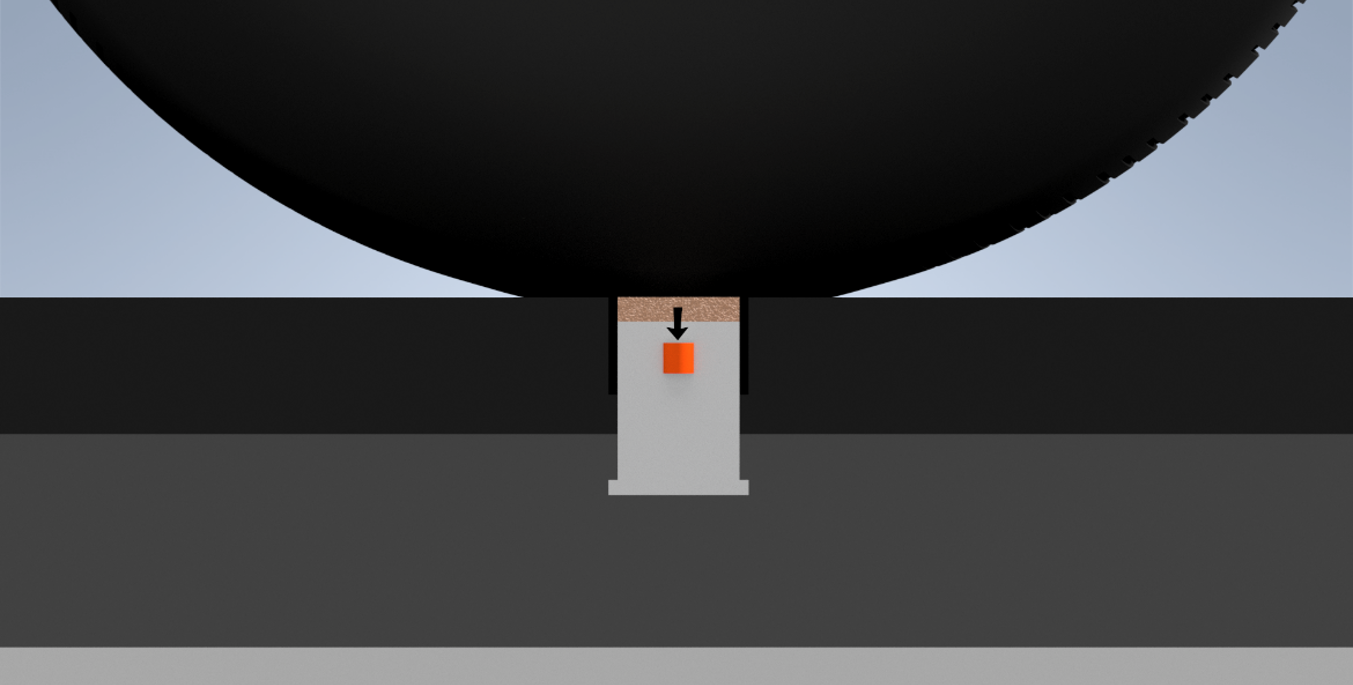

Avoiding Road Damage with a Low Sensor Profile

The sensor’s stiff body may not bend as much as the road it is installed in. This can cause cracks and other damage, especially when the sensor is too high.

Simply put: high sensors which interfere with deep road layers speed up the road wear. Achieving a low sensor profile is key to preserving the road for as long as possible.

WIMTRONIC's (left) total height is only 45 mm. It is, therefore, less intrusive than most other strip sensors (right).

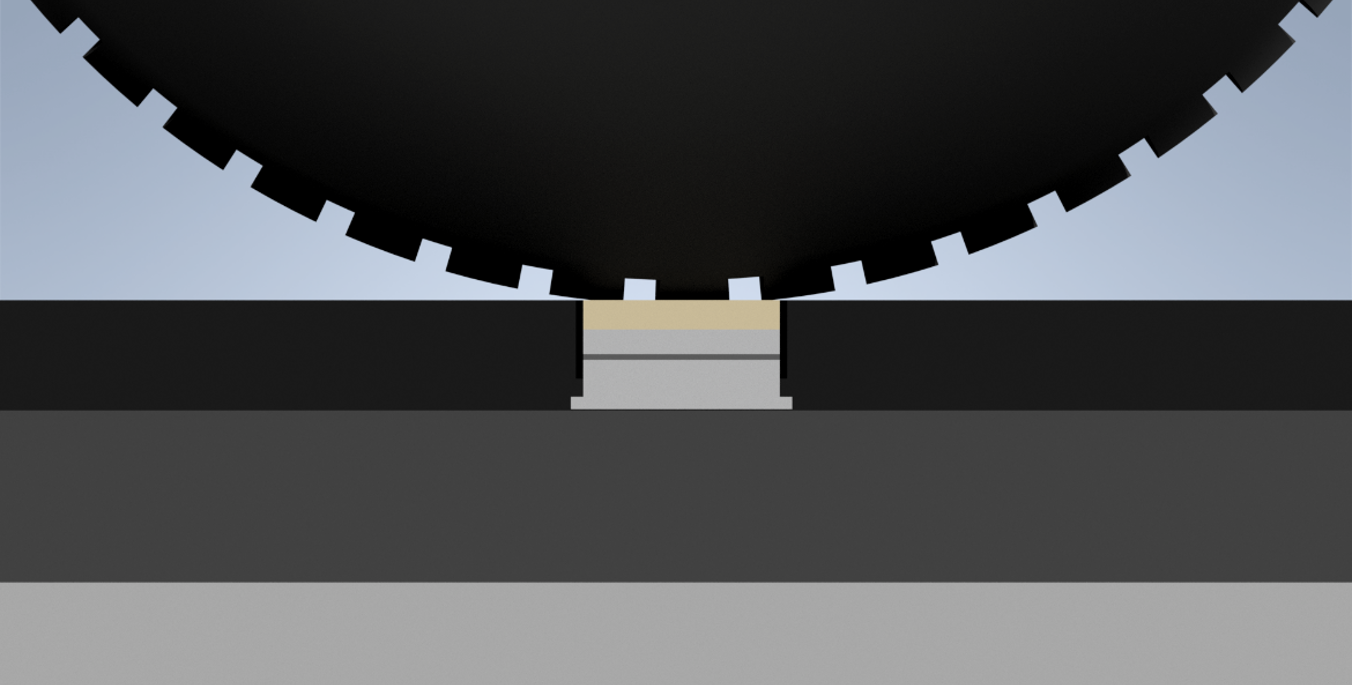

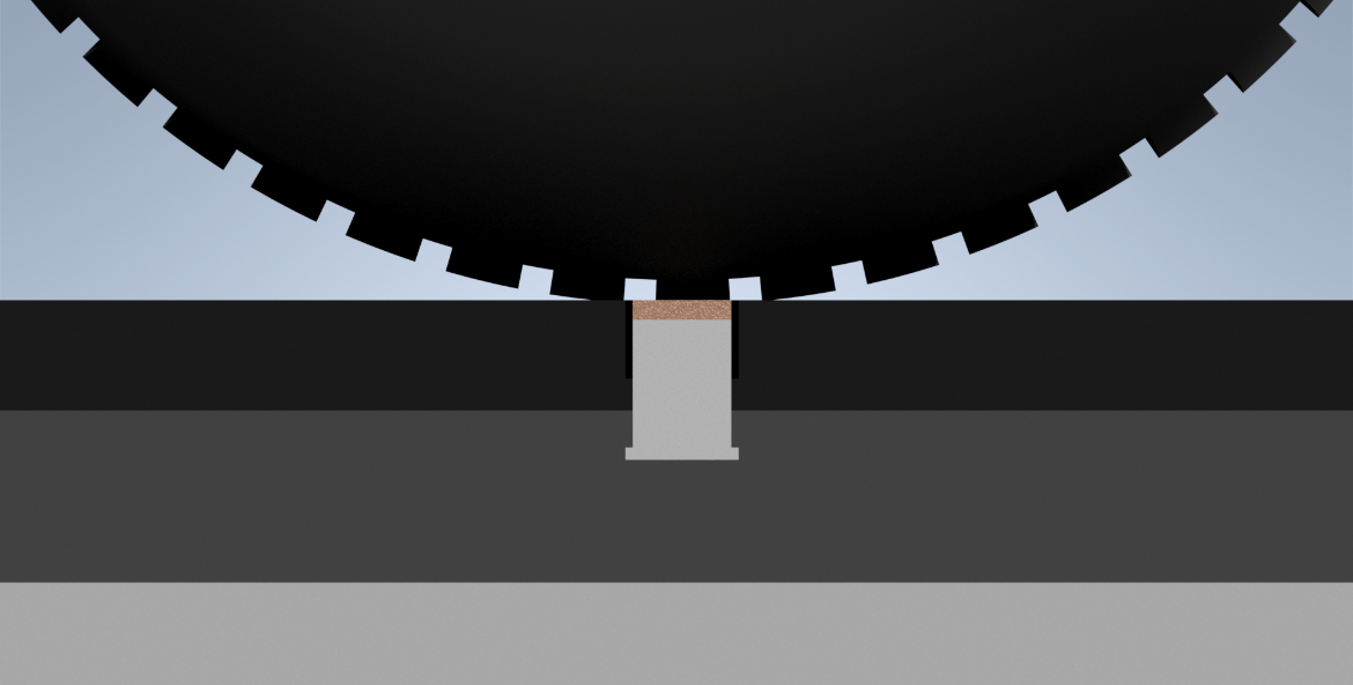

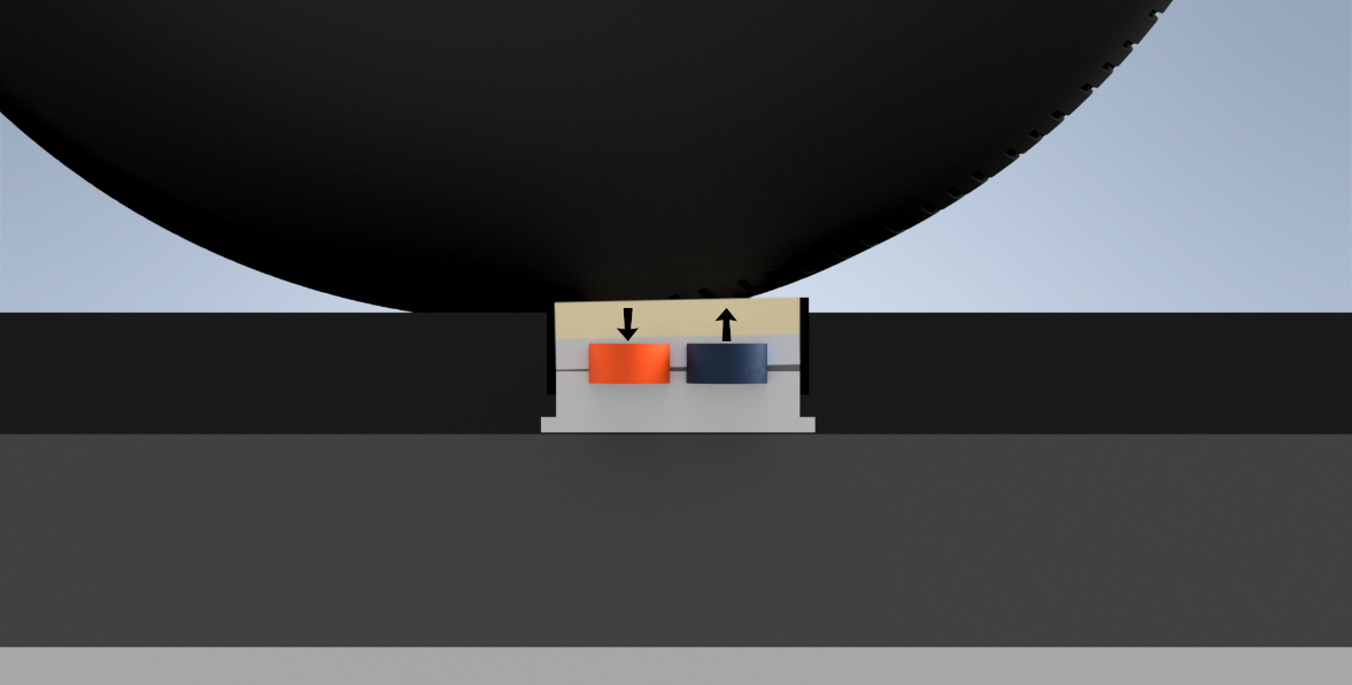

Securing Long Service Life with a High Abrasive Layer

WIM sensors have an abrasive layer on its top. It enables to adjust the sensor surface to the road pavement unevenness, such as ruts caused by heavy traffic.

Although an ideal sensor is as low as possible, sensor developers aim to maximize the thickness of the abrasive layer, so even deep ruts can be addressed by sensor grinding.

Designing a sensor which complies with both requirements mentioned above is a serious technological challenge. We are happy to have achieved unique parameters: WIMTRONIC's very low 45mm body features a 12mm high abrasive layer for an exceptionally long lifespan.

WIMTRONIC's (left) abrasive layer can be grinded to the depth of the ruts and the WIM system can continue its operation. The other sensor (right) needs to be replaced because the height of its abrasive layer does not allow further grinding.

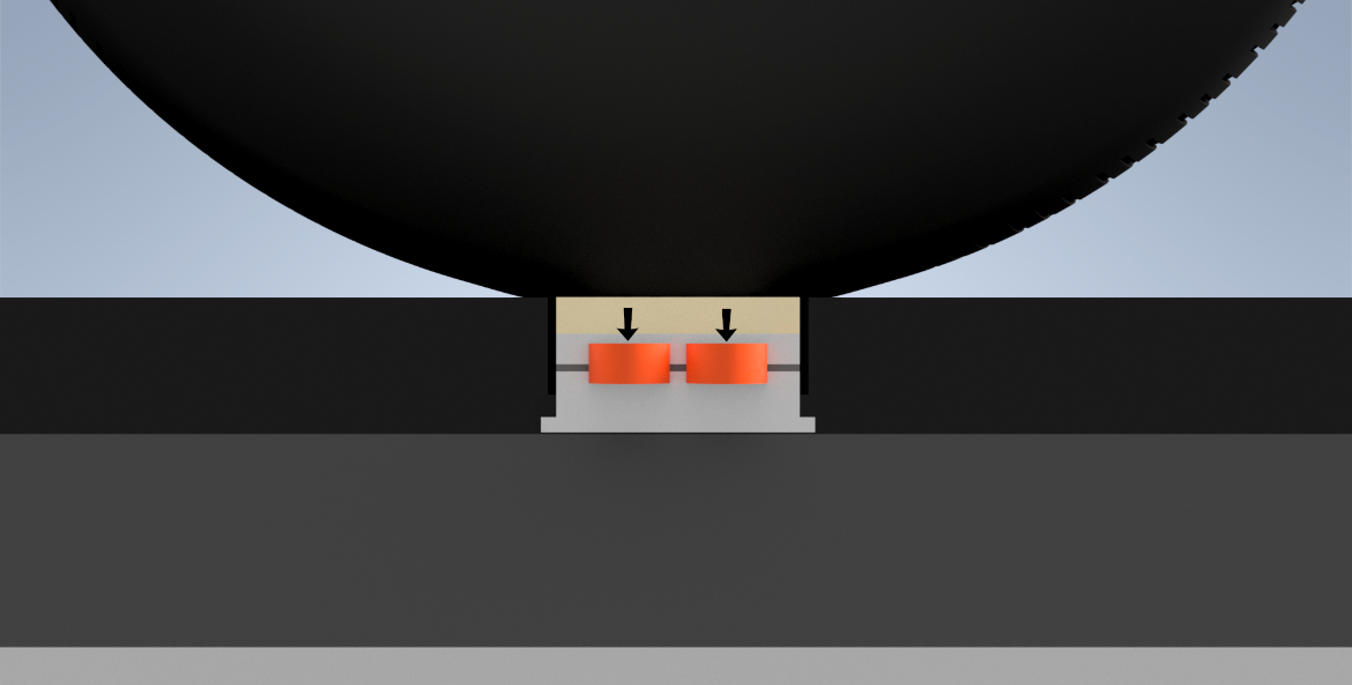

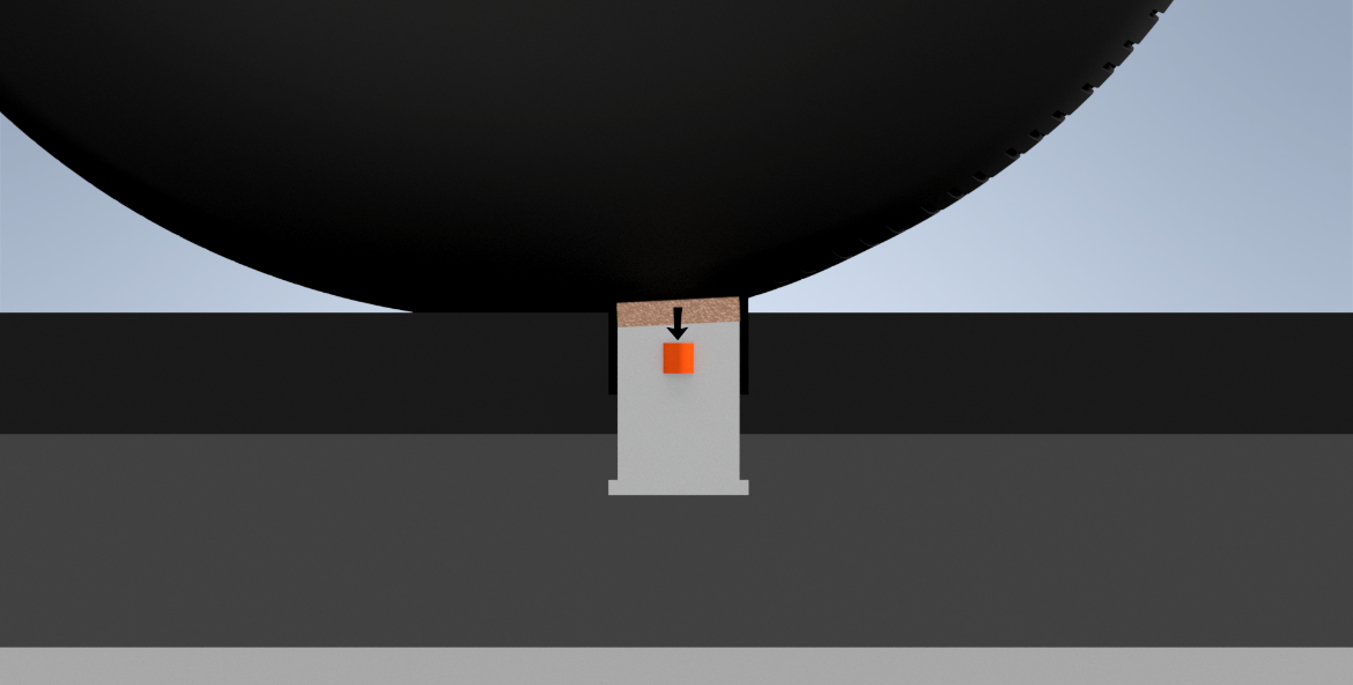

Unique Design for Accurate Weighing

Measurement accuracy is, among other factors, affected by tire pattern and irregularities of the pavement. Maximizing the contact of the wheel and the sensor reduces these factors and helps achieve great results in terms of weighing accuracy.

WIMTRONIC (left) is 80 mm wide and therefore has a longer tire contact than other strip sensors (right; usually 40‑70 mm).

Analog WIM sensors that use a load-cell technology feature one measurement per sensor for each passing vehicle wheel. The load cells in WIMTRONIC are not connected in parallel. This enables independent measurement of responses with more reliable results, as well as novel functions.

The sensing elements can be placed in two or even more rows for multiple measurements to improve accuracy and detect braking, torque, and more maneuvers (left). Other strip sensors (right) miss this feature.

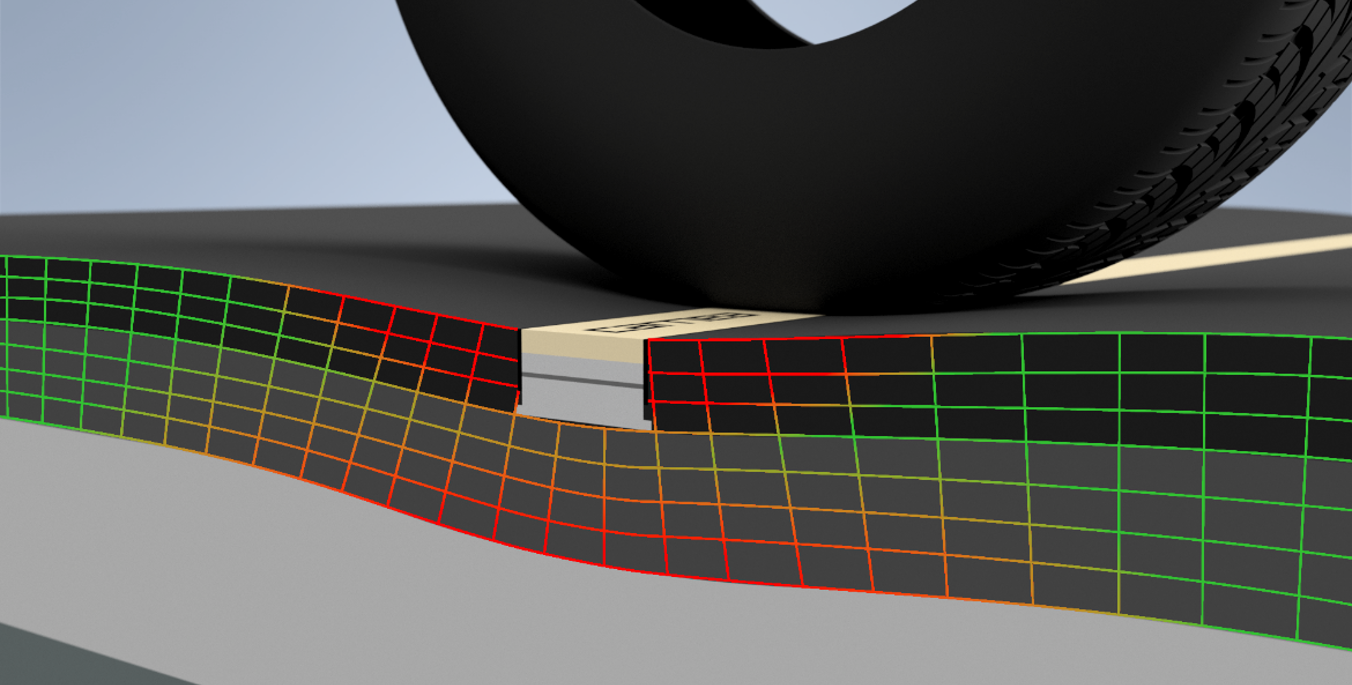

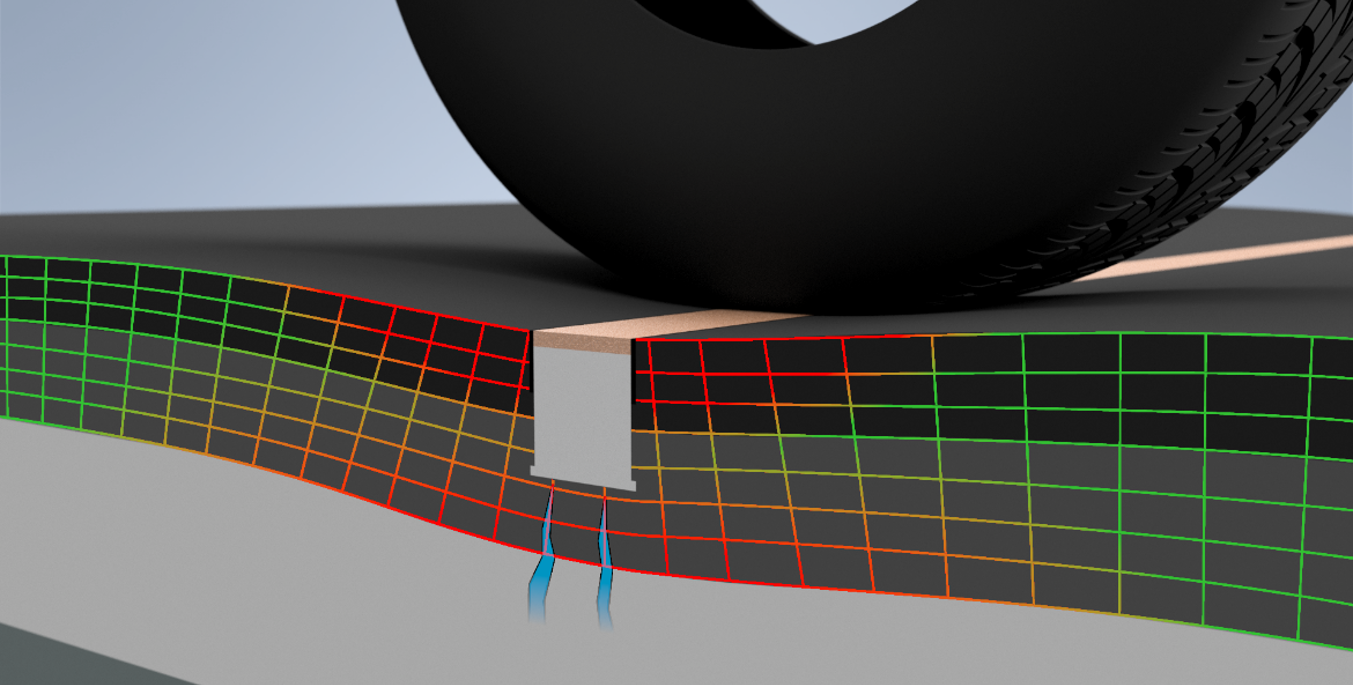

Low Side Bending Effect

High sensors lean to sides when gaining or losing contact with vehicle wheels. Therefore, they are prone to suffering damage, unless made very bulky and heavy.

WIMTRONIC's (left) unique width-height ratio and durable yet not too bulky design result in low side bending. The sensor features greater overload resistance than most strip sensors (right).

Variable Production Length

Each site is different and so are the requirements to cover certain areas with WIM sensors (such as road shoulders). We will provide WIMTRONIC in custom sensor lengths to extend the possibilities for site layouts.

Pushing WIM Evolution Further

On these thirty slides, we summarized everything you need to know about WIMTRONIC

Effects of Direct Enforcement WIM

5×

Lower damage to infrastructure

80 %

Significant number of violation drop in the first months

4 years

Extended road lifespan

CAMEA WIM

One overloaded truck causes as much damage to the roads as almost 30,000 passenger cars. Weigh-In-Motion by CAMEA represents a solution to this by monitoring and eliminating such trucks. In addition, it contributes to traffic fluency and road safety.